Our project

Project scope

SaltHy – Vision meets proven storage technology

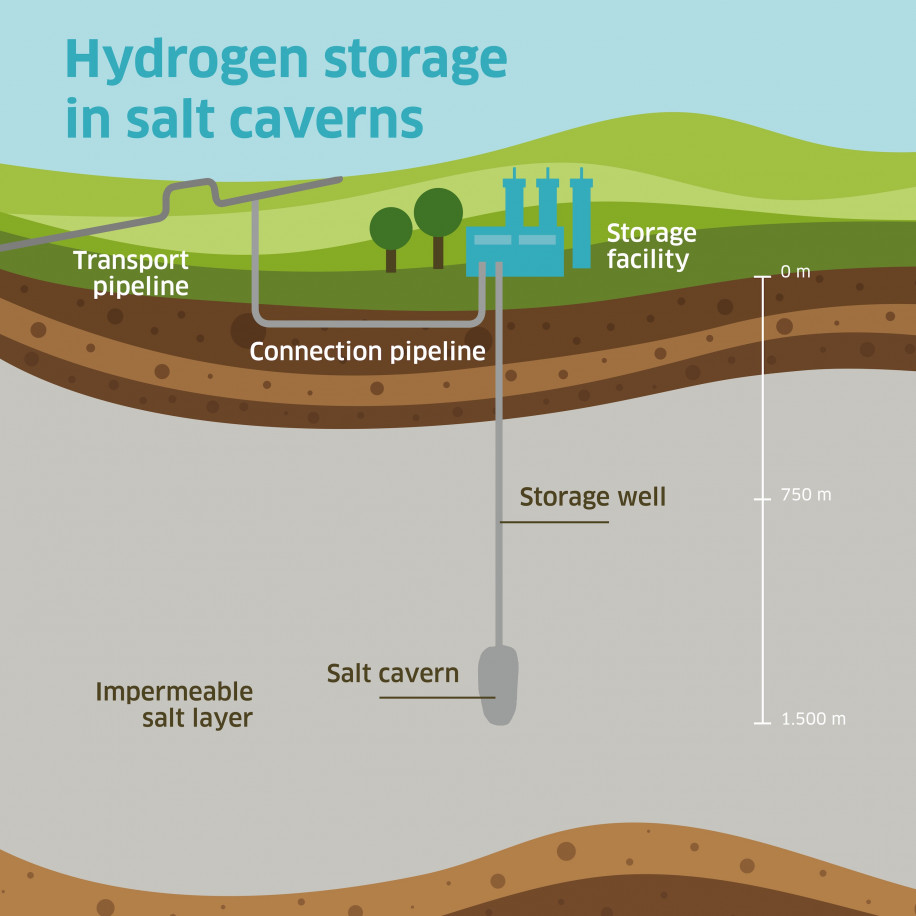

SaltHy is a pioneering project in northern Germany that applies proven salt cavern storage technology to hydrogen. The project entails the construction of one of Germany's first hydrogen storage facilities. With SaltHy, Storengy Deutschland is supporting the market ramp-up for hydrogen in Europe and contributing to the successful achievement of climate goals.

As part of the SaltHy project, Storengy Deutschland is expanding the existing Harsefeld natural gas storage facility with additional salt caverns and associated surface facilities for underground hydrogen storage. SaltHy is a flagship project on an industrial scale. The first cavern will be able to store around 7,000 tons of hydrogen. A second cavern will offer an additional 7,000 tons of storage capacity. Together, the storage capacity will be around 14,000 tons of hydrogen. The storage volume of one cavern is sufficient to cover the needs of a regional steel mill (140 tons of hydrogen per day) for around two months.

The caverns are expected to be created at depths of approximately 1,000 to 2,000 meters. Each cavern will have a geometric volume of approximately 0.5 to 0.8 million cubic meters and will be shaped like a cylinder with a dome-like roof and floor standing in salt. The diameter will be approximately 60 to 70 meters, while the height of the cavern will reach approximately 200 meters.

From 2035 onwards, the two salt caverns in Harsefeld, which are currently still used for natural gas storage, are to be converted for hydrogen storage, provided that there is no foreseeable demand for them on the natural gas market.

Looking to our Storengy colleagues in France: The EU-funded HyPSTER project was launched in January 2021 with the aim of using salt caverns to store hydrogen. Together with other initiatives, HyPSTER aims to advance France's regional hydrogen strategy and promote the development of a local hydrogen hub.

The Etrez site, the largest salt cavern storage facility in France, offers ideal conditions for this. The location is strategically located for European gas transporters, as it is at the center of the “European Hydrogen Backbone.” HyPSTER will therefore be able to increase the flexibility and security of supply of the cross-border hydrogen network. The export of hydrogen to Germany is also part of the project planning. Another goal of the project is to verify the technical and economic replicability of the process in order to ultimately optimize the price of hydrogen for end consumers. Findings and experience from the HyPSTER project will also be used for the SaltHy project in Harsefeld.

Additional information on the HyPSTER project is available on the project website.

Additional information on the HyPSTER project is available on the

EU funding

SaltHy is a Project of Common Interest (PCI)

SaltHy is on the current Union list of Projects of Common Interest (PCI) published by the European Commission. PCIs are key cross-border energy infrastructure projects that contribute to the EU’s energy and climate policy objectives. These projects are eligible for funding from the Connecting Europe Facility (CEF) and benefit from accelerated permit granting according to trans-European energy infrastructure rules (TEN-E Regulation).

More information on the PCI 9.22.1 “SaltHy hydrogen storage Harsefeld” can be found on the PCI-PMI Transparency platform and in the project fiche.

SaltHy is co-funded by the EU

SaltHy has secured 4,471,750.50 € in EU funding from the Connecting Europe Facility (CEF) to carry out studies. CEF is a funding instrument that aims to promote growth, jobs and competitiveness in Europe through targeted investment in cross-border infrastructure. It supports the development of projects in the areas of transport, energy and digital services. In the 2024 call for funding for PCI projects in the energy sector, Storengy applied for funding for studies, i.e. preparatory measures for project implementation. The total project volume for these studies amounts to around nine million euros, 50 percent of which can now be covered by the CEF funding.

Objective of the EU-funded studies project (“PSISHarP”)

The PSISHarP (Preparatory Studies for the Implementation of the SaltHy hydrogen storage Harsefeld Project) project contributes to the implementation of PCI 9.22.1-“Salthy hydrogen storage Harsefeld”, which consists of the construction of an underground hydrogen storage and more particularly the creation of a new salt cavern and construction of dedicated surface facilities to store 100% H2, and which will be connected to the H2 network of Gasunie running from the Netherlands to Denmark via Hamburg. The Harsefeld salt dome potentially allows for the creation of several caverns, enabling the following extension options: 2nd phase with another cavern and the necessary surface equipment & 3rd phase: repurposing to H2 of existing natural gas facilities.

The current project aims at ensuring SaltHy’s readiness for full implementation and alignment with EU energy transition goals, particularly under the REPowerEU strategy. The project includes studies in the areas of engineering (subsurface, surface, and leaching plant), permitting & stakeholder management as well as risk, HSE, and quality management.

The successful completion of the PSISHarP project will lead to the development of detailed engineering and contracts for material and services necessary to start cavern construction (well and leaching plant), basic Engineering (FEED) for the surface facilities as basis for a sound Final Investment Decision (FID), updated Environmental Impact Assessment (EIA) and submission of the necessary permit applications. These outcomes will pave the way for further development steps at the Harsefeld site or at other locations, but also position the SaltHy project to play a crucial role in the development of the European hydrogen economy, contributing to energy security, market integration, and the achievement of climate goals.

Additional information on our CEF project “9.22.1-DE-S-M-24-PSISHarP” is available on the EU Funding & Tenders Portal.

Co-funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the European Climate, Infrastructure and Environment Executive Agency (CINEA). Neither the European Union nor the granting authority can be held responsible for them.

SaltHy participates in the EU-funded FrHyGe project

Storengy Deutschland is also a partner of the FrHyGe project (Full qualification in France for large-scale hydrogen underground storage and replication from Germany to all European countries). FrHyGe is dedicated to validating large-scale underground hydrogen storage in salt caverns. Launched on 20 March 2024, this innovative project is led by a European consortium of 17 partners and coordinated by Storengy in France.

With a total budget of 43 million euros – 20 million of which is funded by the Clean Hydrogen Partnership – FrHyGe aims to advance the future of renewable hydrogen storage in Europe, opening new opportunities for sustainable energy development. The demonstrator project at the site of Manosque (south of France) consists of technical, economic, regulatory, environmental, and safety studies. Based on these studies, a plan will be drawn up to start deploying the technology across Europe.

The role of SaltHy in the FrHyGe project is to replicate successful demonstrator results at commercial scale. SaltHy benefits from studies carried out under this project, which are not covered by CEF funding.

The project is supported by the Clean Hydrogen Partnership and its members.

Go to the FrHyGe Website and the EU Funding & Tenders Portal for more details.

Co-funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the Clean Hydrogen Partnership. Neither the European Union nor the granting authority can be held responsible for them.

Functioning of the storage facility

The gas transport pipeline (1) transports hydrogen throughout Europe. A shorter connecting pipeline (2) connects the storage facility directly to this network. When hydrogen is withdrawn from the network for storage, it first flows through an inlet filter (3) to remove any impurities. The hydrogen then passes through a gas flow meter (4), which also records its quality. The downstream compressor station (5) compresses the hydrogen to the current cavern pressure, causing it to heat up and requiring it to be cooled down (6) before further transport. It finally reaches the salt cavern deep underground via the cavern head (7), where it is stored safely.

When needed, the hydrogen is withdrawn again. To do this, it flows out of the cavern via the cavern head and first passes through a filter separator (8) to remove any impurities. In order to be decompressed from the cavern pressure to the pressure of the connecting pipeline, the hydrogen must then be cooled (9), as it heats up during decompression. It then flows through a gas treatment plant (10) to ensure that the quality requirements of the gas transport pipelines are met. Immediately before being fed back into the connecting pipeline, the hydrogen is metered and its quality (4) is checked. It is then fed back into the transport pipeline via the connecting pipeline and transported through this network to the consumer.

The SaltHy project team is currently working on the conceptual design for the surface facility, which will describe the main components of the facility, their layout, and their impact on the environment. In addition, planning is also underway for the subsurface facility, including for the sinking and equipping (completion) of the borehole and the necessary ancillary facilities.

Parallel to the planning phase, mapping work in the project area began at the end of March 2024. The project area is located between the two villages of Hollenbeck and Harsefeld in the district of Stade. The surrounding area is largely characterized by agricultural land, forests, and small settlements. The project area is crisscrossed by country roads and dirt tracks. Two watercourses, the Hollenbeeke and the Riesbrockgraben, run through the southern part of the area. The Harsefeld underground storage facility is located within the area.

Based on the results of the planning and the findings from the mapping, the company will carry out a preliminary environmental impact assessment and submit the documents to the responsible permitting authority (LBEG mining authority in Hanover). After reviewing the documents, the State Authority for Mining, Energy and Geology will decide whether a comprehensive environmental impact assessment is required for the entire project. The further permitting steps depend on this decision.

The sinking of the first borehole is planned for 2026. Between 2027 and 2032, the first hydrogen salt cavern at the Harsefeld site will be leached. Discussions are currently underway with a regional industrial partner to ensure the sustainable reuse of the salt obtained during leaching.

Construction of the surface facilities belonging to the storage facility will begin in 2030. These include, among other things:

- Inlet filter

- Gas volume measurement

- Compressor unit(s) with gas recooling

- Field pipeline with cavern connection

- Filter separator

- Gas cooling and condensate separation

- Gas drying plant/gas treatment plant

According to the current schedule, the commissioning and initial filling of the Harsefeld hydrogen storage facility is planned for 2032.

Parallel to the completion of the first salt cavern, work is beginning on a second new hydrogen salt cavern.

Conversion of existing natural gas caverns will follow once it becomes apparent that the storage capacity is no longer required in the natural gas market.

With the phasing out of natural gas use in Germany, the existing natural gas storage facilities in Harsefeld will also be converted for hydrogen storage. In the long term, only hydrogen will be stored at the Harsefeld site.

With the expansion and new construction of the underground storage facilities, Storengy Deutschland is investing locally in future-proofing of the Harsefeld storage site. This will help secure jobs at the site in the long term. After the facility’s commissioning, experienced regional companies are scheduled to be contracted for maintenance and servicing work. Additionally, from that time onward, Storengy Deutschland will pay local property and business taxes for the hydrogen storage business in Harsefeld, just as it currently does for the natural gas storage operations.

Storengy Deutschland remains deeply committed to biodiversity and maintaining strong local ties with the community. In this spirit, fruit trees have been planted on the natural gas storage site, photovoltaic panels installed, wildflower meadows created and beehives set up. Furthermore, regular collaborations with local organizations and volunteer fire brigades are carried out. We look forward to continuing this engagement!

Both in the ongoing operation of our natural gas storage and in the construction and future operation of our hydrogen storage, we are committed to adhering to the highest safety and environmental standards. In particular, sustainable and resource-efficient use of by-products is a priority during construction. Currently, negotiations are underway with a regional industrial partner regarding the utilization of the salt extracted during cavern leaching.

Storengy Deutschland is developing and implementing a comprehensive safety concept that detects potential risks arising from the operation of the facility at an early stage. In close cooperation with local authorities and the volunteer fire brigade, the facility’s safe and flawless operation is ensured. Compliance with all safety standards is regularly monitored by the responsible authorities during both construction and normal operation. The design of the cavern piping, installed monitoring and safety systems, as well as recurring inspections, guarantee the safe operation of the cavern.

Before commissioning, detailed geomechanical studies were conducted to optimally determine the dimensions and operating conditions of the new caverns. Regular cavity measurements and monitoring of surface subsidence above the cavern enable early detection and tracking of any ground settlement. While surface subsidence cannot be entirely ruled out, it is harmless within defined limits.

Gas storage in caverns is a proven and reliable solution. The surrounding rock provides robust protection against external influences and acts as a natural barrier to the environment. Since no oxygen is present in the caverns, the risk of an explosion inside the storage facility can be ruled out.

The existing caverns owned by Dow are unsuitable for hydrogen storage because they are designed to be far too large for this purpose. Additionally, these caverns were built for a specific use, meaning they have a "brine shape" and are not technically (in terms of piping) designed or convertible for hydrogen use.

Yes, SaltHy receives public funding from the European Union. SaltHy is recognized as a “Project of Common Interest” (PCI) and is co-financed by the EU under the Connecting Europe Facility (CEF). SaltHy has received approximately €4.47 million in EU funding for preparatory studies, including engineering for subsurface and surface facilities, permitting procedures, stakeholder management, and risk, HSE, and quality management. This funding covers 50% of the costs of the studies and prepares for the implementation of our storage project. In addition, SaltHy is part of the EU-funded FrHyGe demonstrator project, which validates large-volume underground hydrogen storage and is supported by the Clean Hydrogen Partnership.

Further information:

• CEF funding project description

Storengy Deutschland will not produce hydrogen in Harsefeld but will only provide storage capacities for hydrogen, which are essential for a functioning hydrogen market. The chemical element hydrogen is colorless.

The color designation refers to the production method. Green hydrogen generally means hydrogen produced by water electrolysis powered by renewable electricity. Green hydrogen is indispensable for achieving the net-zero target.

However, for a rapid market ramp-up, the National Hydrogen Strategy also foresees the transitional use of other types of hydrogen, such as so-called blue hydrogen (produced by steam methane reforming combined with Carbon Capture and Storage of the separated CO2). Whether and to what extent hydrogen other than green hydrogen will still play a role at the time of the Harsefeld storage facility’s commissioning cannot be determined today.

This cannot yet be definitively predicted today. The EU assumes an annual hydrogen demand of 20 million tons from 2030 onwards. It has set itself the goal of producing 10 million tons of hydrogen domestically and importing the remaining 10 million tons from various partner regions. In northern Germany, which is an important pillar of the EU Hydrogen Backbone, hydrogen will be both produced directly and imported in large quantities in the future. Germany’s key hydrogen hub is currently being developed in the Stade region, where the Harsefeld storage facility is also located. So whether locally produced or imported: there will be ample storage demand in the region from 2030 onwards.